These sensors are used as classical ballistic pressure sensors, for example, in monitoring the combustion behavior of ammunition or propellant charges, but are also used in many other applications outside of ballistics, such as in the automotive industry (airbag development), Industrial areas (hydro-forming) or in the medical industry (lithotripsy by ultrasound). All applications target the precise measurement of extremely rapid pressure increases of more than 1000 bar/µs and in some cases, extreme maximum pressures of up to 8,000 bar.

...like our Pressure Sensor

H-8

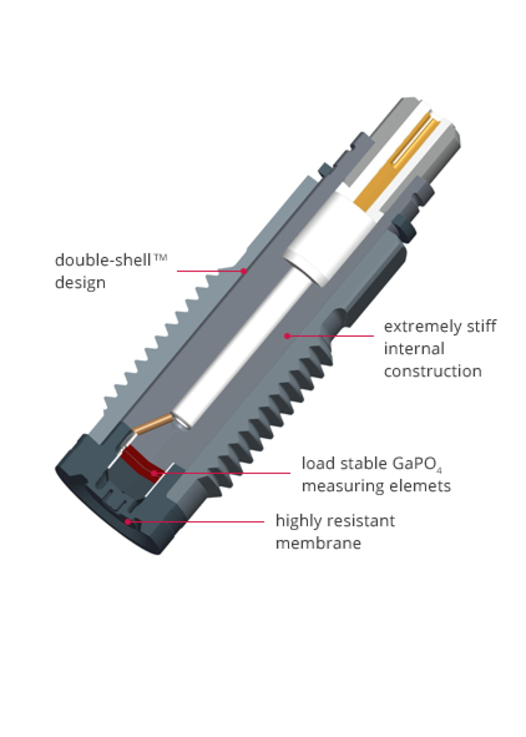

With the H-8, measurements up to 8,000 bar are now possible within the dimensions of an M10 bore. This sensor has excellent specifications for linearity (≤ ± 0.5%) and sensitivity (2.5 pC/bar) and is characterized by its very rigid structure for precise measurement of extremely rapid pressure rises and therefore best suitable for ballistic measurements.

Sensor Technology

Due to the low sensitivity of the quartz used, the sensitivity of sensors available on the market is not always adequate. Piezocryst sensors are equipped with GaPO4 crystals. They have all the well-known and reliable characteristics of quartz, but are twice as sensitive. For the sensors with a measuring range of up to 2000 bar, this is a significant performance improvement over the current state of high pressure measurement technology and a significant improvement in data quality. For sensors with a range of 6000 to 8000 bar, this is expressed in a significantly improved signal-to-noise ratio.

Under extreme pressure an extremely rigid sensor construction is required to prevent any disturbance due to hysteresis and the associated restoring forces. Piezocryst high-pressure sensors are based on special load-stable crystal cuts in longitudinal effect. These sensors have a special Double Shell™ construction, which decouples the sensor from disturbances within the installation environment. In addition, due to the extreme need for compressive strength and thermal shock independence, the membrane must be made of high-performance alloys with very narrow tolerances to ensure durability and signal quality. Another important factor in performance is the seal. Piezocryst has developed a special sealing system that will stay safely sealed under high-pressure gradients and mechanical shock, while distributing the resulting forces so that the Double Shell™ housing is not subject to interference. This gives measurement results in a new kind of data quality.

The product range includes pressure sensors for measuring ranges up to 2000, 6000 and 8000 bar. All of these sensors have an M10 thread, so that measurements of different pressure ranges within one bore are possible.